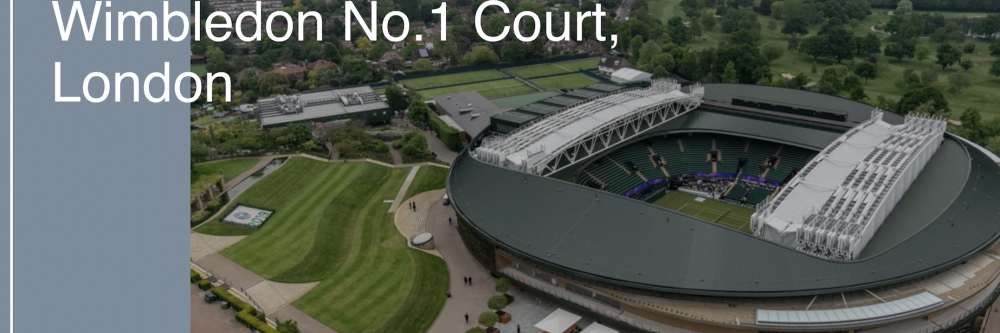

Wimbledon No.1 Court, London

Wimbledon is a summer staple, a British institution, so we were thrilled to play a role in its redevelopment. We helped give Wimbledon No. 1 Court a bespoke new structure to support the sliding roof system - much like that of its famous counterpart, Centre Court.

This project fits in with our desire to leave a meaningful legacy in some of the country’s most iconic spaces and buildings.

The overall project included the roof structure and extensions to the hospitality levels around the stadia, to add more hospitality suites and increase open spaces for viewing the rest of the complex. Further works also included the new Walled Garden and Aorangi Café, plus an upgrade to the building facade to create a more modern environment around No.1 Court for when the eyes of the world descend in summer.

Our work on this saw us provide five large truss units to support the very complex inner roof structure. These trusses were installed in manageable sized sections, using our own temporary works system and bespoke units, designed to work in harmony for the gradual de-jack of each portion of the roof.

These trusses needed to be tied together with the inner roof and this meant the creation of a braced, lattice structure which cantilevers off the larger trusses and is fixed by a tension ring at the innermost portion of the roof. For us, the tension ring posed one of the more challenging aspects of the project. A gradual de-jack and lowering of the roof was needed and we worked with the engineer and main contractor to ensure this was completed safely and professionally.

We also had the opportunity to provide our in-house Seversafe temporary edge protection system and metal deck system when creating plant decks and an outer roof system to the rear of the trusses. These plant decks are to support the stadia’s vast plant and air conditioning units - very important for regulating the temperature on and around court.

The new roof has an element of 11 moving trusses, with each truss being approximately 75 metres long and having an average lift weight of 93 tonnes! Because of the sheer size of these elements, this section was pre-assembled on two of the practice courts in preparation for the installation.

This was a complex and unique structure and one we’ve been thrilled to work on.